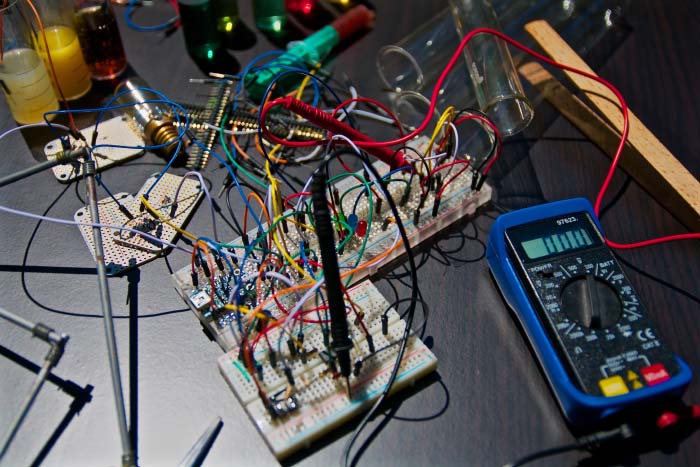

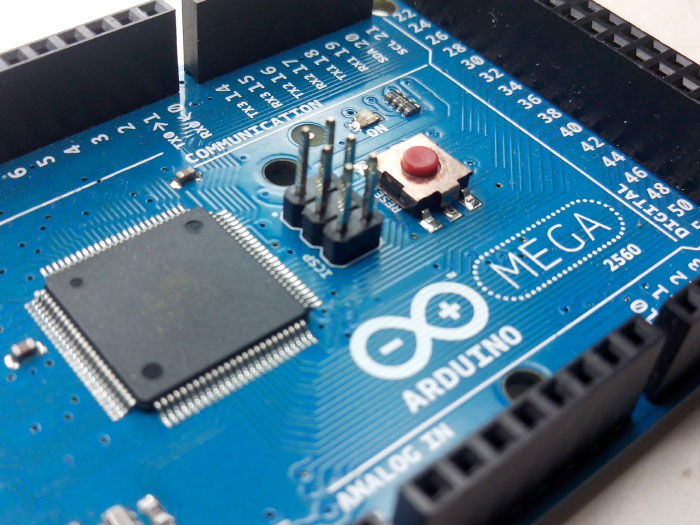

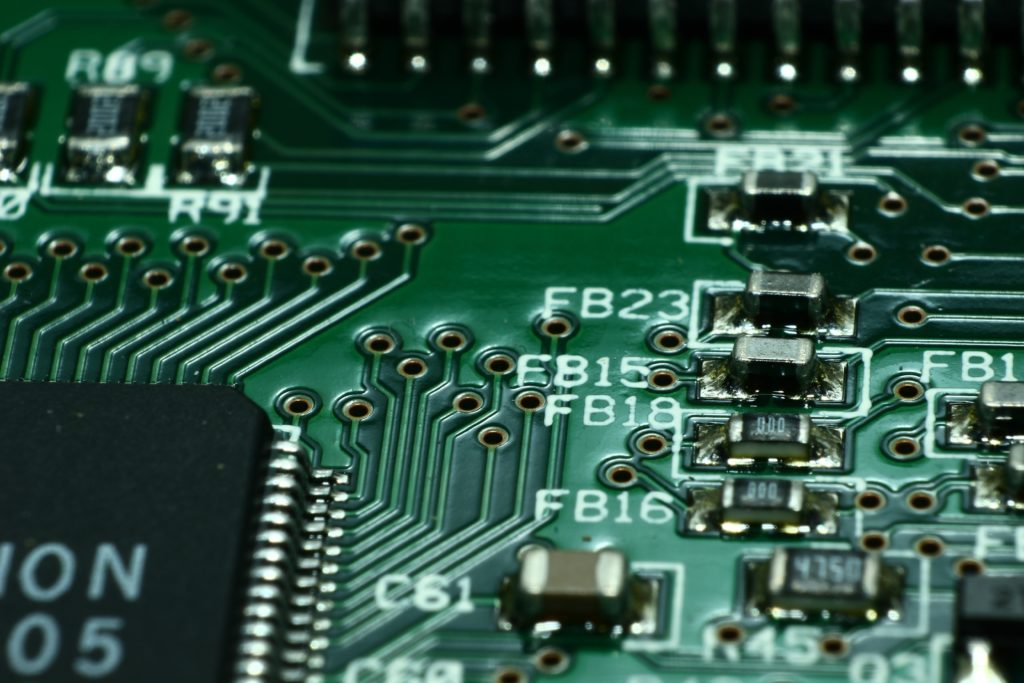

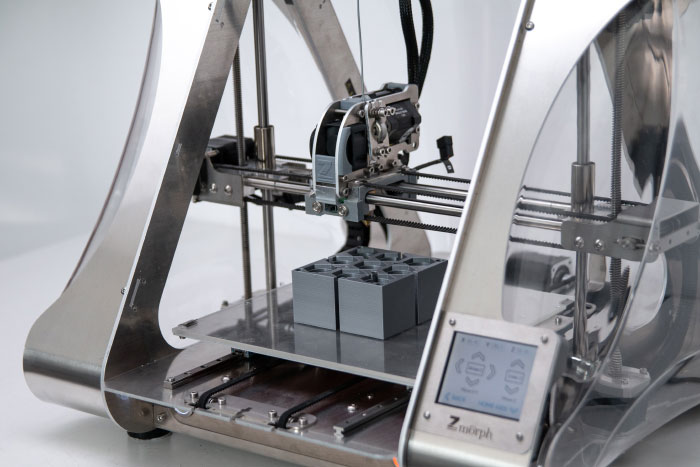

Rapid prototyping is relevant for all PCBs, electronic components, and plastic housing parts. From microcontrollers and circuit boards to 3D printed cases, making your ideas physical helps you to discover potential issues and fix problems before manufacturing. We provide practical prototypes at all stages of the development cycle, with multiple revisions available before we lock down a final design.

Through rapid prototyping, you can highlight your vision and share your design with the world. Attractive and functional prototypes will enable you to showcase products and obtain valuable feedback from clients and stakeholders. In addition to PCBs and electronic parts, we specialize in 3D printing and additive fabrication models for plastic enclosures.