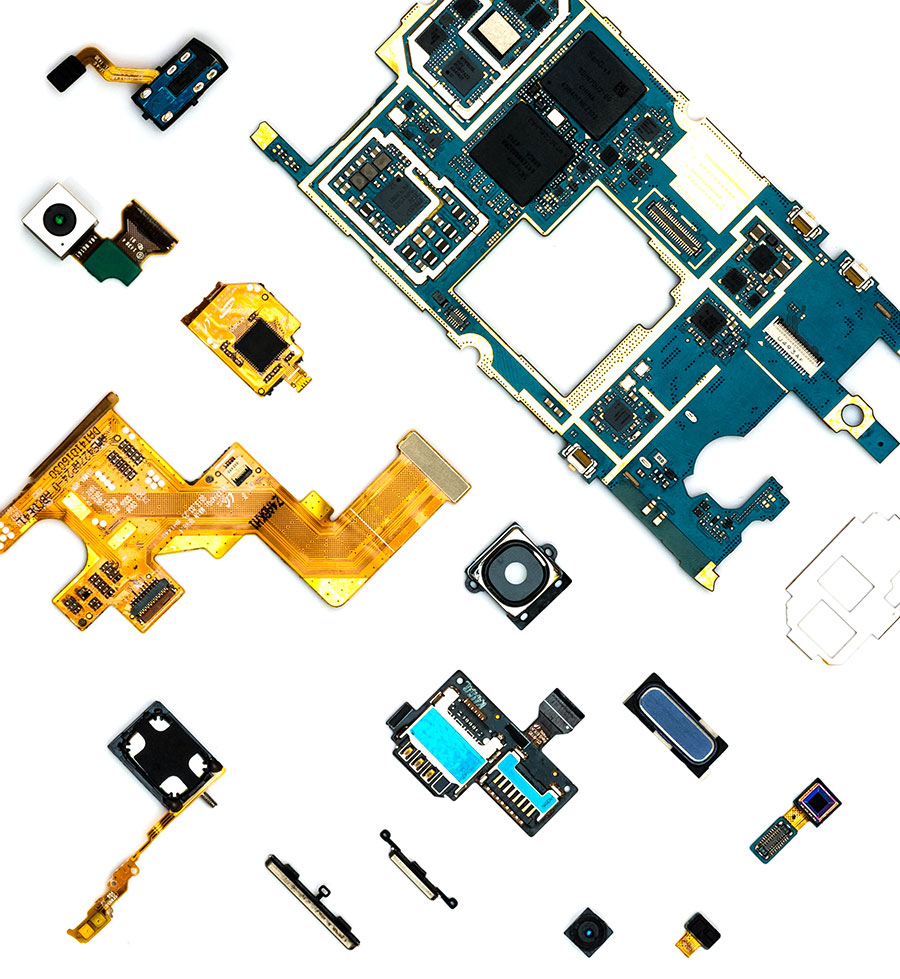

We buy boards, source parts, and assemble PCBs directly for your project. Our designs and assembly capabilities cover through-hole technology (THT) and surface mount technology (SMT).

When you work with MicroType, you can expect consultation, integration, and quality throughout the assembly process:

- Bare circuit boards are ordered from one of many trusted fabrication houses.

- Solder paste is applied to the bare boards using a high-end DEK screen-printer.

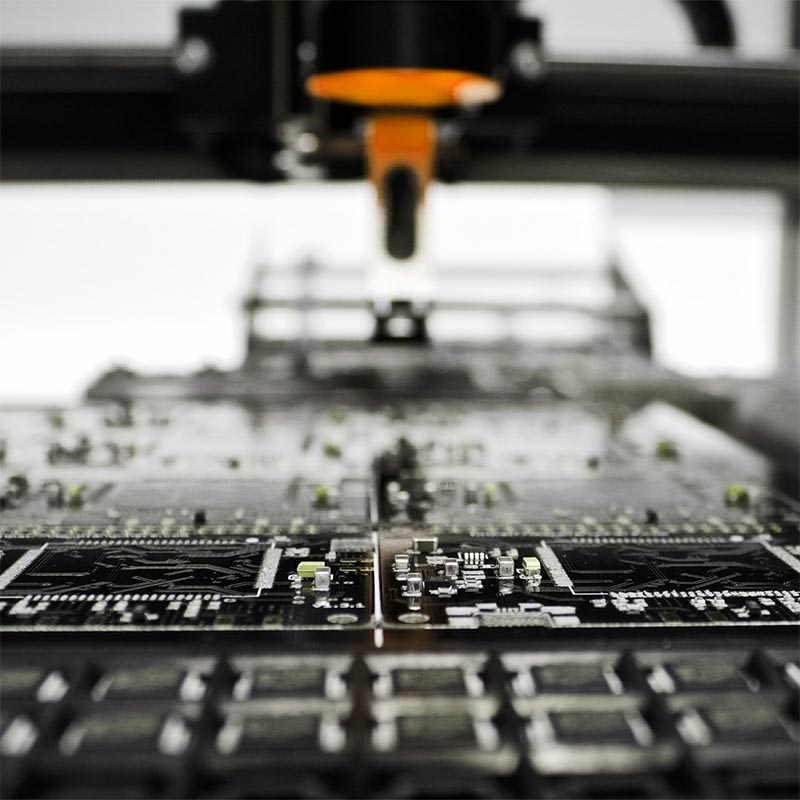

- A Phillips “Pick and Place” machine rapidly places all surface-mount components.

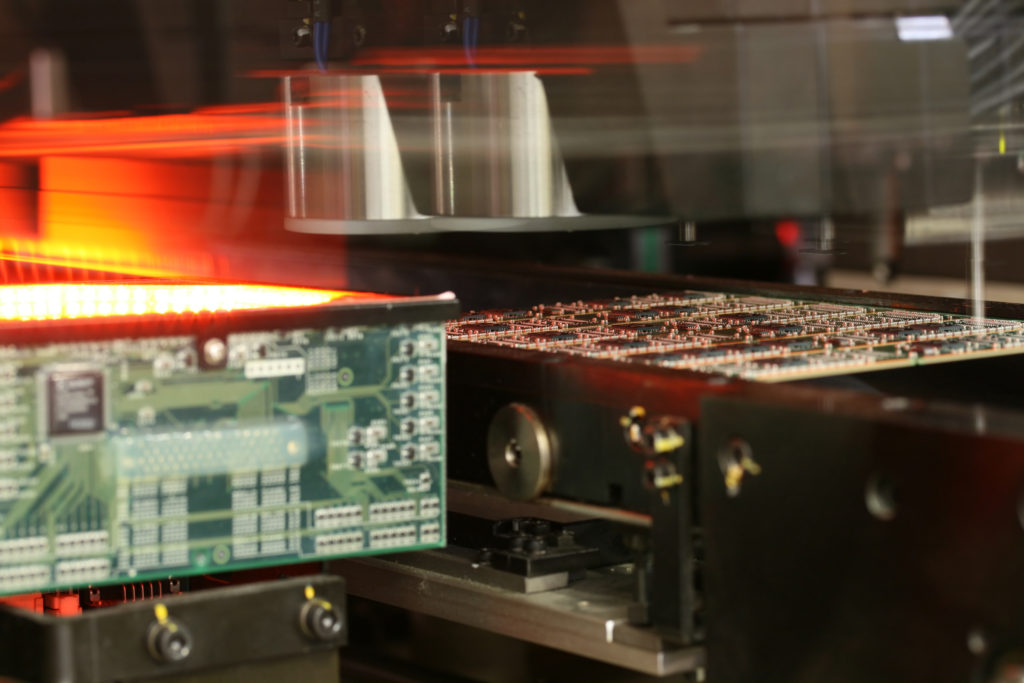

- The boards go into a large reflow oven that melts the solder and attaches the components.

- Through-hole components are manually placed on the boards, and a selective soldering machine quickly solders all components.

- Each board is visually and functionally tested to ensure high-quality control standards.

- If the board passes testing, a unique serial number is affixed for full traceability.

If you’re looking for a complete PCB assembly solution, please contact us for online quotes or schedule a meeting with our friendly team.