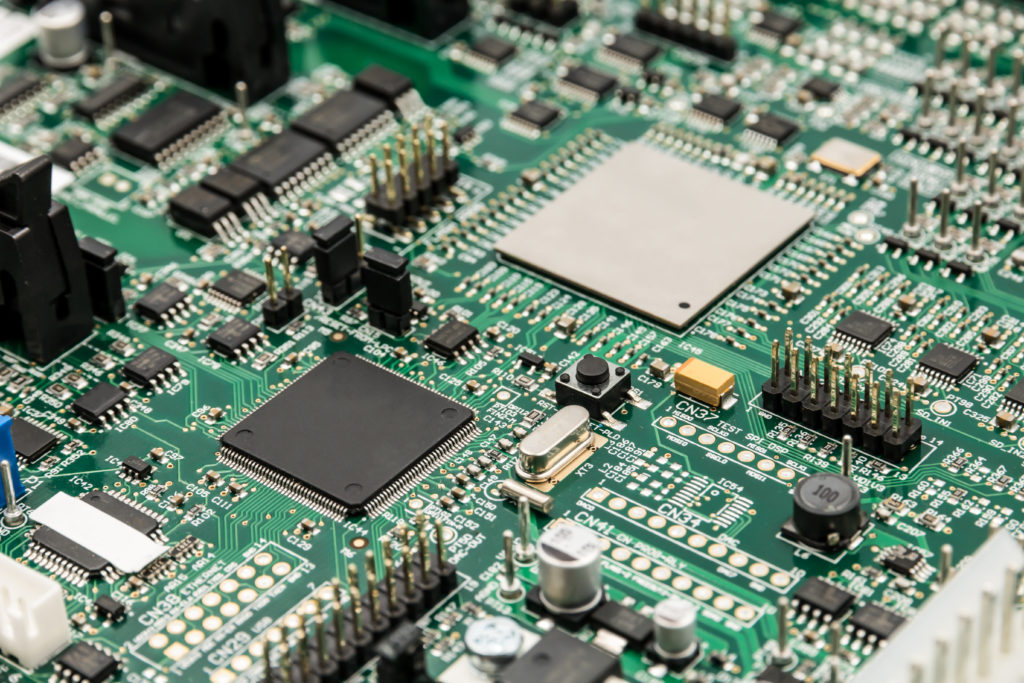

At MicroType Engineering, we specialize in both through-hole technology (THT) and surface-mount technology (SMT) and have the ability to test and assemble circuit boards based on your exact needs. We specialize in high-value, low-mid volume PCB assembly in the range of 1-1000 circuit boards per month.

Are you looking for a simple and complete prototyping solution? Our integrated prototyping service includes all aspects of design and fabrication. Creating functional PCBs and components for rapid prototyping helps to identify usability and design issues early in the development process.